A cutterhead is a crucial component used in jointers, planers, and other woodworking machinery, and choosing the right one can significantly impact the efficiency and quality of your woodworking projects. Cutterheads come in two popular types: Spiral cutterhead and helical cutterhead. Regarding helical and spiral cutterheads for wood planers and jointers, there is a bit of confusion. While both terms refer to a form of winding around the cylindrical shaft, the recessed grooves that the knives are positioned along on the cutterheads are different. We will then explain their distinctive features, how nice the finish is, and their typical applications. Hopefully, this guide will help you decide which one is right for your project by looking at some of the details that set them apart.

What are helical and spiral cutterheads?

Spiral cutterheads consist of a cylindrical shaft with rows of small square indexable carbide inserts placed close together in a spiral pattern. These indexable inserts are made of carbide, and tungsten carbide is the second toughest substance in the world, so these hard tungsten insert knives possess a lengthy lifespan and require minimal maintenance. Moreover, since the cutting action of carbide inserts is segmented across the whole cutter head diameter, as opposed to at two or three certain spots, they are also marginally quieter than straight knives.

Helical cutterheads, on the other hand, feature a row of square carbide insert knives around a cylindrical shaft in a helical pattern, each set on an angle following the helix. This structure provides a smoother wood surface than a traditional straight cutterhead. Carbide inserts are better than straight knives because carbide insert generally has 4 cutting faces that can be individually indexed 90 degrees, so if you damage any knives, or they get dull, you can always rotate inserts to expose a fresh cutting edge. This also extends the service life of helical cutterheads. In addition, one of the probably most important benefits of helical cutterheads is the reduction of tear-out through a shearing cut action. On challenging woods or high-density materials, helical cutterheads usually result in significantly smoother finishes.

Helical vs. Spiral Cutterheads Comparison Insert arrangement

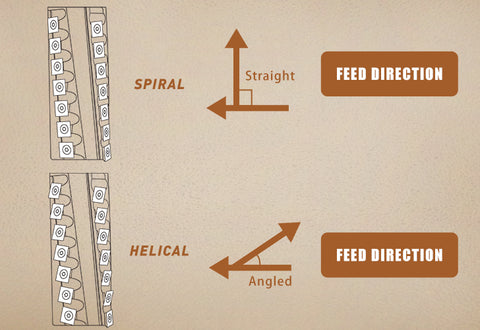

The main difference between helical and spiral cutterheads lies in the orientation of each knife. A helical cutterhead features indexable carbide inserts that are aligned along the axis of rotation but have an inclined angle, typically around 14 degrees. Carbide inserts are mounted at a slight angle to the path of the workpiece. Helical cutterheads provide a shearing cut due to the inclined angle of the inserts to the direction of the workpiece, resulting in smoother wood surface finishes and reduced tear-out than spiral cutterheads. Conversely, The installed inserts of a spiral cutter head are aligned parallel to the axis of rotation, with no title angle. This means that the cutting edges of carbide inserts are oriented perpendicular to the direction of the workpiece travel.

Application

Spiral cutterheads are primarily used for cutting softwood and low-density materials where the cutting forces are relatively low. The spiral orientation of the inserts allows for efficient chip evacuation, making them suitable for materials that generate a significant amount of waste during the cutting process. In contrast, helical cutterheads find primary applications in cutting hardwood, high-density materials, and challenging-to-process materials. Carbide inserts on helical cutterheads are positioned at a slight angle, creating a shearing action that helps reduce tear-out and produces a smoother surface finish, even on difficult materials. In short, compared to spiral cutterheads, helical cutterheads regularly produce smoother surface finishes and less tear-out, which makes them suitable for fine woodworking projects.

Initial cost

A helical cutter head is more expensive than a spiral one. The complicated process of creating helix angles between each knife makes the engineering and precise manufacturing of helical patterns far more costly. In addition, helical cutterheads tend to utilize more carbide inserts than spiral cutterheads, which drives up the cost even further.

Which one is a better choice?

Although both types of cutterheads can cut through wood, each has its benefits and matches during the woodworking process. So, does all of this imply that helical cutterheads are superior to spiral cutterheads? Not necessarily. Even though spiral cutterheads are typically more affordable upfront, helical cutterheads may end up being more valuable in the long term because of their higher longevity and performance. The choice between spiral and helical cutterheads ultimately boils down to various factors, including the types of wood, budget considerations, and desired finish quality. While spiral cutterheads are great at generating better finishes on hardwoods and exotic materials, helical cutterheads are ideal for heavy-duty woodworking operations because of their exceptional performance and durability. With that in mind, a helical cutterhead can be an ideal fit for seasoned woodworkers or someone with no budgetary constraints.

FindBuyTool supplies fine planer/jointer helical cutterheads with top-quality tungsten carbide insert knives mounted, spiral cutterheads, as well as carbide insert knives. Our helical cutter head offers a better finish, reduced sound, and smaller chips, and saves you on maintenance. If you cannot find a cutter head for your machine model, we also provide an option for a custom cutter head.