1. Butt Joint

To start with, a butt joint is the most basic wood joint because it simply butts two pieces of wood together. Since this wood joint can’t lock each board together, it needs glue or countersinking nails to stay in place.

Application: Butt joints are often used around window trims and baseboards.

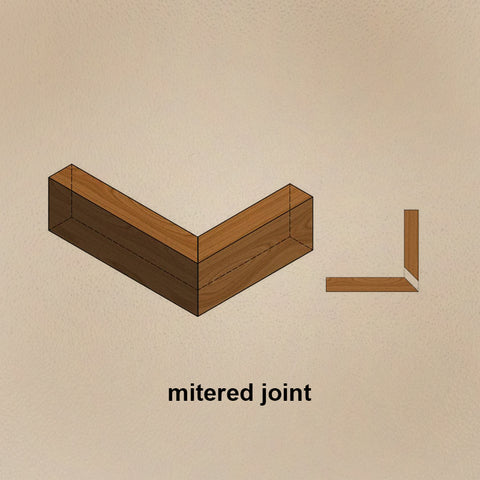

2. Mitered Joint

A mitered joint is also a basic wood joint. Unlike a butt joint, a mitered joint joins two boards at an angle, most commonly 45-degree. But a mitered joint can be cut at any angle according to your project.

Application: It is often used at door, window, and picture frames. Like butt joints, mitered joints still need glue to stick two boards together.

3. Half-Lap Joint

To create a half-lap joint, we need to cut half the thickness of two boards at their joining point so that the two wood boards overlap each other. This type of joint is stronger than the butt joint and mitered joint.

Application: Half-lap joint is ideal for frames as well as furniture making for their thickness.

4. Tongue and Groove Joint

A tongue and groove joint contains a tongue on one piece of board and a groove on the other. Sliding the tongue into the groove to form a strong tongue and groove wood joint.

Application: This joint is often used for hardwood flooring and beadboards making.

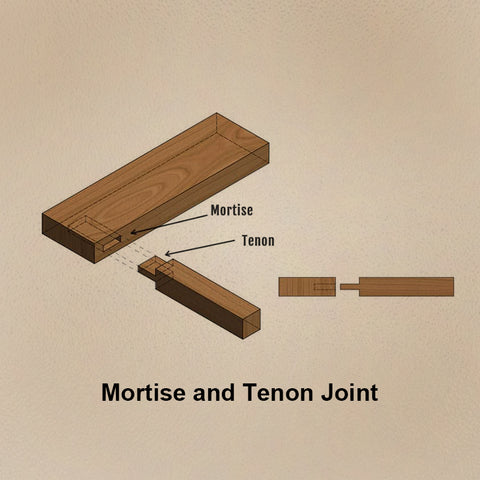

5. Mortise and Tenon Joint

Mortise and tenon joint was invented for ancient construction, so it is a very classic wood joinery method. Till now, this joint is still one of the strongest and most beautiful wood joints for buildings and frames. It requires high precision to finish a mortise and tenon joint. Remember to cut the mortise first since it is easier to cut a tenon to fit the mortise.

Application: It is mostly used in crafts and furniture making.

6. Biscuit Joint

Biscuit joint is used to join wood boards by cutting slots into two boards and using a biscuit (a wood wafer) to hold them together. This joint is completely invisible, thus forming a perfect surface.

Application: Biscuit joint is ideal for making tabletops, boxes, drawers, etc.

7. Box Joint/Finger Joint

Box/Finger joint is to cut a series of symmetrical slots to create rectangular fingers at the end of two boards. Since there isn’t mechanical strength in the box joint, we need glue to hold it in place.

Application: Finger joint is ideal for making floorboards, baseboards, doors, etc.

8. Dado Joint

along the wood grain direction whereas the dado joint is cut across the wood grain. When cutting a dado joint, remember that the deep of the dado should be at least 1/3 into the board.

Application: Dado joints are ideal for making cabinets and bookshelves.

9. Rabbet Joint/Rebate Joint

The rabbet or rebate joint is another most commonly used wood joint in cabinetry. We create a rabbet joint by cutting a recess along the end of a wood board. Although the rabbet joint looks simple, it is greatly stronger than the butt joint.

Application: A rabbet joint is most used in building the back of a cabinet for combining the back to the sides of the cabinet box. Besides, this joint can also be used in making windowsills or door frames with glass inserts.

10. DovetailJoint

A dovetail joint is often recognized as a sign of high-quality craftsmanship. To form dovetail joints, we cut a series of trapezoidal-shaped interlocking pins and tails at the end of the boards. A dovetail joint features high resistance from pulling apart.

Application: This joint is ideal for building drawers, connecting the sides of a drawer to the front part.

1 comment

Juniorhorsford