A cutterhead is an important part used in jointers, planers, and other woodworking machines. And the types of it decide the effect and efficiency of the woodworking project.

Cutterheads have two categories: spiral and helical. Some beginners may be confused about them due to the synonym. Both of them are similar in outlook, and the difference lies in the position of the knife arrangement.

In this guide, we will explore their features, uses, differences, and how to choose them in different situations. Hope it can help you choose the most compatible cutterhead for your project.

What are Helical and Spiral Cutterheads?

Spiral cutterheads have a cylindrical shaft and place a row of square indexable carbide inserts in a spiral pattern. The cutting action of these inserts does not concentrate at two or three specific spots, but across the whole cutterhead. Thus, they are quieter than straight knives.

Helical cutterheads only place rows of square indexable carbide inserts in a helical pattern on the cylindrical shaft. And every one of these inserts has been set at a specific angle, which makes the helical cutterhead reduce the tear-out, especially when cutting some hardwoods or high-density materials.

Both spiral and helical cutterheads use indexable carbide inserts, which are made from tungsten carbide. Due to the characteristics of the material, these inserts have a long lifespan and low maintenance costs.

On the other hand, each insert can be individually indexed 90 degrees. Therefore, if a single edge of the insert is dull or broken, you can rotate the inserts to expose a new cutting edge until all the edges are unavailable, then you can change to a new one.

Related Read: Helical vs Straight Cutterhead: Which One Do You Choose

Helical vs. Spiral Cutterheads Comparison

Knowing what these two cutterheads are, now, here comes the key part of this blog: the main differences between these two cutterheads.

Insert arrangement

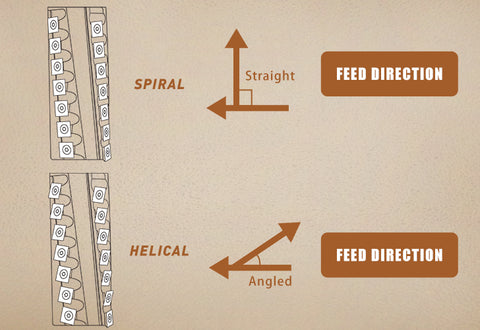

The main difference between helical and spiral cutterheads lies in the direction of the inserts' arrangement. The inserts on a spiral cutterhead have no tilt angle. Thus, when contacting the workpiece, the whole cutting edge is vertical to the direction of the workpiece.

On the contrary, the inserts on a helical cutterhead have an inclined angle of around 14 degrees. When contacting the workpiece, there will be an inclined angle between them, resulting in a shearing cut and gaining a smoother surface.

Application

Compared to helical cutterheads, the cutting ability of spiral cutterheads is lower; thus, they are more suitable for cutting softwood and low-density materials. On the other hand, the direction of the insert arrangement makes efficient chip evacuation; thus, they are also suitable for materials that will produce a large amount of chips.

Helical cutterheads are more compatible for cutting hardwood, high-density materials, and difficult-to-process materials. The tilt angle of the inserts can reduce marks left on the material surface during cutting, making it ideal for fine woodworking projects.

Initial cost

A helical cutter head is more expensive than a spiral one. The complicated process of creating helix angles between each knife makes the engineering and precise manufacturing of helical patterns far more costly.

In addition, helical cutterheads tend to utilize more carbide inserts than spiral cutterheads, which drives up the cost even further.

Which One is Better?

These two cutterheads have their advantages and disadvantages, but which one is better, or how to choose them for your woodworking projects? It depends on the types of wood, processing method, project type, and your budget.

But if you say which one is better, we think it's the helical one. Spiral cutterheads are gouging the material, while helical cutterheads are slicing it. From this point, definitely, the helical one brings less impact against the workpiece surface, produces less noise, and makes it last longer.

So we recommend you purchase a helical cutterhead, especially when you use it on a thickness planer. It's absolutely worth the price. With higher performance, longevity, and practicality, it is also a good choice for heavy-duty woodworking projects and can help you tackle various tasks effortlessly.

FindBuyTool supplies fine planer/jointer helical cutterheads with top-quality tungsten carbide insert knives mounted, spiral cutterheads, as well as carbide insert knives. Our helical cutter head offers a better finish, reduced sound, and smaller chips, and saves you on maintenance. If you cannot find a cutter head for your machine model, we also provide an option for a custom cutter head.

Related Read:

How to Choose the Best Cutterhead for DeWalt 735 & 735X

[2025]The 6 Best Benchtop Thickness Planer

FAQ about Spiral & Helical Cutterhead

#1 Which is better, helical or spiral cutterhead?

Helical cutterhead. With higher performance, longevity, and practicality, they can handle various materials to gain a smoother surface and reduce the noise and vibration.

#2 Is a spiral the same as a helical?

Definitely not. Although these two words are synonyms, they are totally different. The main difference lies in the arrangement of the insert. The insert on the helical cutterhead has a tilt angle while the spiral does not.

4 comments

Thank you for the informative article. There are some confusing contradictions though:

“Spiral cutterheads are primarily used for cutting softwood and low-density materials where the cutting forces are relatively low.”

“While spiral cutterheads are great at generating better finishes on hardwoods and exotic materials,…”

“So, does all of this imply that helical cutterheads are superior to spiral cutterheads?

Not necessarily. Even though spiral cutterheads are typically more affordable upfront, helical cutterheads may end up being more valuable in the long term because of their higher longevity and performance."

So.. You’re saying helical are always superior? Or not? I’m confused.

Two points, here. First, a synonym is a word that overlaps in meaning; it doesn’t mean that it’s a substitute word. Second, the article explains that the angle of the carbide inserts is what makes the difference between the two.

Two points, here. First, a synonym is a word that has overlapping meanings; it does mean that it’s a substitute word. Second, the article explains that the angle of the carbide inserts is what makes the difference between the two.

helical is a synonym for spiral so…… wtf are you talking about!!!!!!